April 2025

Senior Research Analyst

Reviewed By

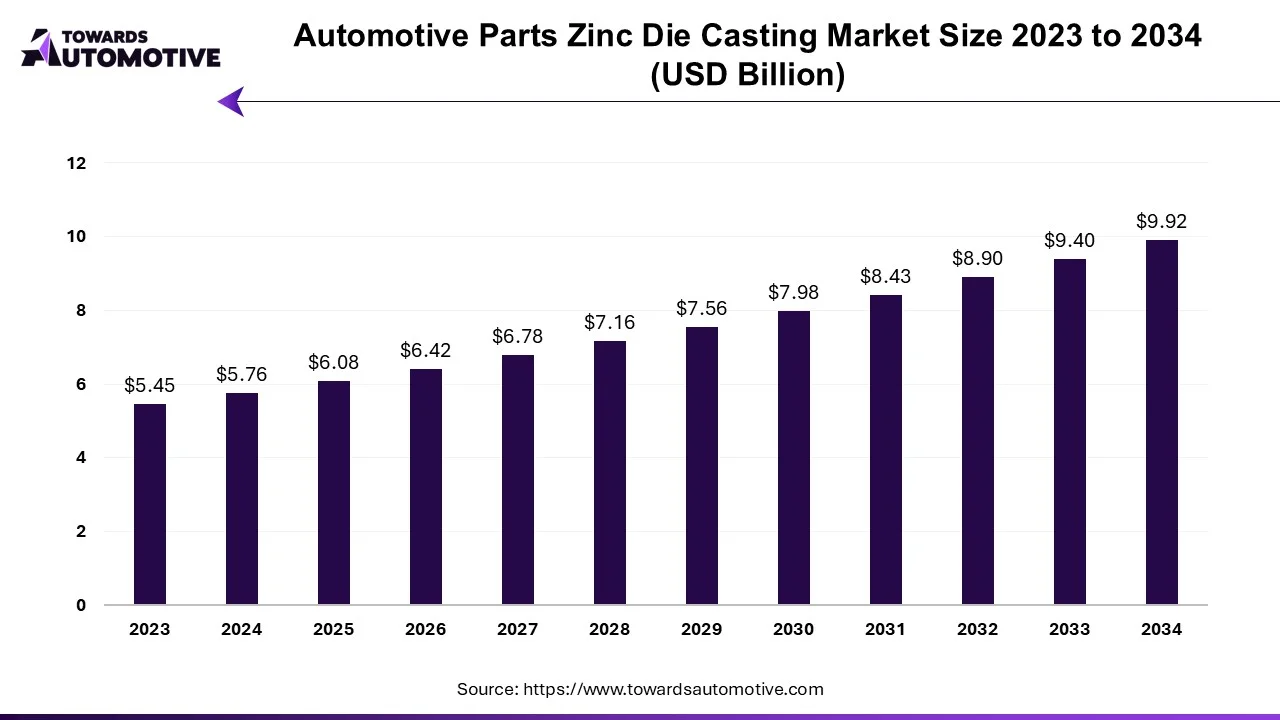

The automotive parts zinc die casting market is projected to reach USD 9.92 billion by 2034, expanding from USD 6.08 billion in 2025, at an annual growth rate of 5.6% during the forecast period from 2025 to 2034.

The COVID-19 pandemic disrupted business focus for 2020, mainly due to a decline in global auto sales and production. Global auto sales fell 16% in 2020 compared to 2019. All major car-producing countries saw declines from 11% to nearly 40%. Europe accounts for approximately 22% of global production. However, with the start of automobile production in mid-2020, the market began to grow. In 2021, global auto sales will continue to increase over 2020.

In the long run, lightweight cars are becoming increasingly popular among automakers because they increase the fuel economy of the car by using lightweight automotive materials to create significant products. The increase in consumer demand for automotive safety products will also bring growth in the market. Because zinc die castings are used in the production of car safety parts, including other parts such as seats, brakes and sunroof.

To reduce vehicle emissions and increase fuel efficiency, CAFÉ standards and EPA regulations are forcing automakers to reduce vehicle weight by using stainless steel. The adoption of die castings as a weight reduction strategy is a major driver in the automotive industry. Although heavier than aluminum, these materials' lower cost and higher hardness make them better for certain applications.

Some automobile companies focus on zinc parts because zinc casting products go directly into the assembly process because zinc casting products already have a better quality, which reduces the special process. Zinc die castings generally have better properties (such as toughness) and better thermal and electrical properties compared to other die castings; This will increase the demand for zinc die castings in automobiles.

For example:

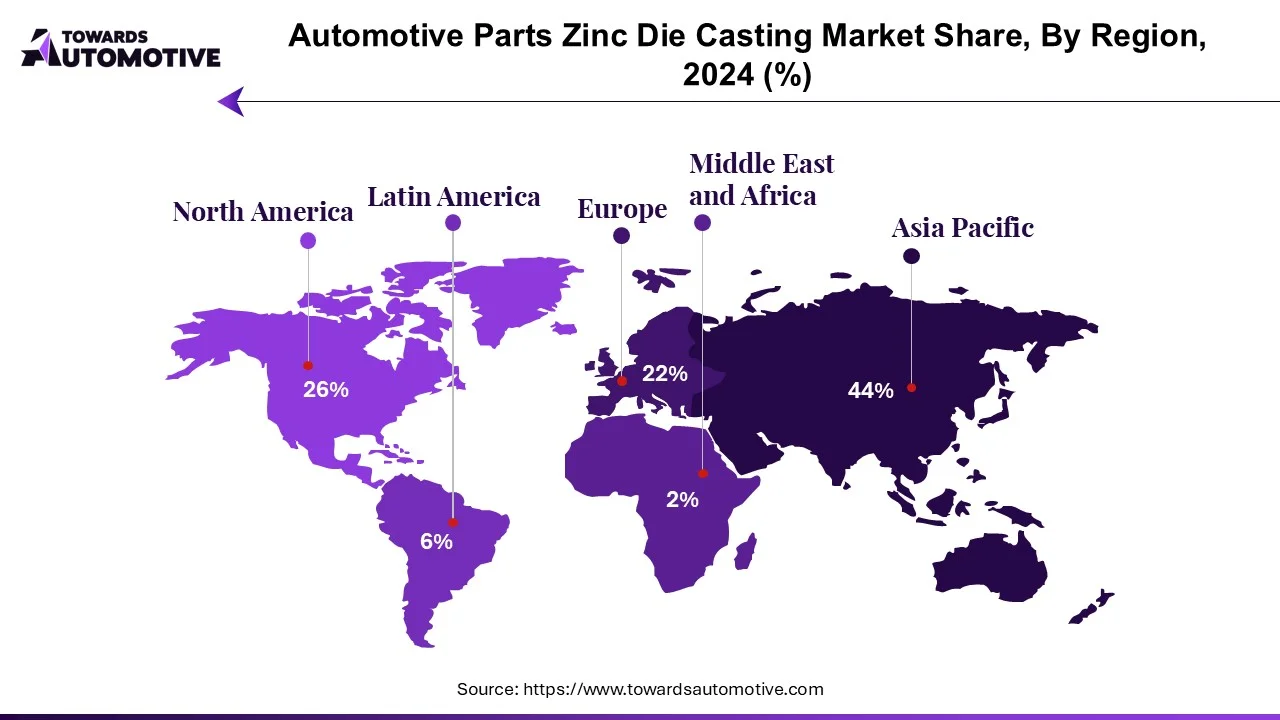

The automotive parts zinc die casting market is dominated by the Asia-Pacific region, followed by Europe and North America. With the development of light vehicles and the expansion of business and production, the automotive zinc die casting market in the Asia-Pacific region is growing rapidly. India is improving its position thanks to strong domestic and international demand for quality zinc die castings at low cost. The rapid expansion of small and medium-sized enterprises in the region will lead to economic growth.

The Chinese government plans to ban all diesel and gasoline vehicles by 2040, provide subsidies to automakers and encourage consumers to use electric vehicles. Increased production of electric vehicles such as passenger cars and commercial vehicles will support the sale of vehicles made from dead materials.

The European automobile industry is the most technological and innovative industry in the world. Due to the economic and political crisis, reducing fuel consumption and CO2 emissions has become an important criterion for automobile manufacturers in the region. This was achieved thanks to reduced weight of the car and better design and structure, which seems to be the best solution at the moment.

European Non-Ferrous Casting's average production per worker is 20 tons and the maximum is 58 tons. Additionally, more than 80% of the castings produced in Europe are delivered to the European region.

For example:

Die casting is pouring molten metal into a mold cavity at high pressure to make a custom-shaped object. Zinc metal is more accessible to cast than aluminum or magnesium metal. Zinc die casting has high productivity, excellent quality, and cost-effectiveness. Zinc die castings make vehicle parts, including seat belts, windscreen wipers, sunroofs, and chassis. The automobile parts zinc die casting industry is divided into three segments: production process, application type, and region.

By Production Process Type

By Application Type

By Geography

April 2025

April 2025

April 2025

April 2025

Dr. Arjun Patel is a distinguished expert in the automotive industry, holding advanced degrees in Automotive Engineering and Mechanical Engineering. His expertise spans automotive market dynamics, technological advancements, and sustainable practices. Dr. Patel excels in conducting in depth research and analysis on market trends, consumer preferences, and the economic implications within the automotive sector. He is renowned for his insightful publications on topics such as electric vehicles, autonomous driving technologies, and the evolution of sustainable transportation solutions. Dr. Patels research contributions have significantly advanced understanding in the field, earning him recognition as a leading authority in automotive research and analysis.

We offer automotive expertise for market projections and customizable research, adaptable to diverse strategic approaches.

Contact Us