April 2025

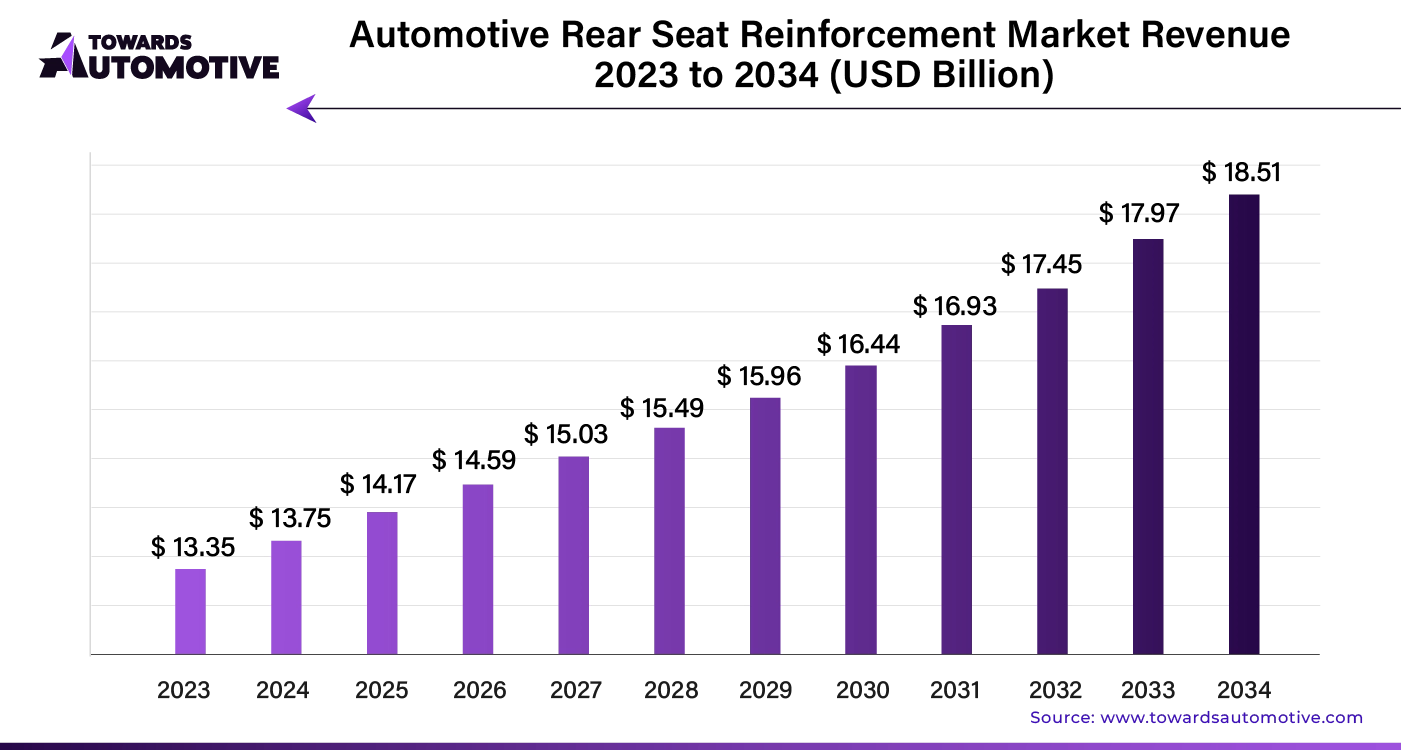

The automotive rear seat reinforcement market is predicted to expand from USD 14.17 billion in 2025 to USD 18.51 billion by 2034, growing at a CAGR of 3.02% during the forecast period from 2025 to 2034.

Unlock Infinite Advantages: Subscribe to Annual Membership

As the first point of contact between passengers and their vehicle, the car seat significantly impacts the overall driving experience. Recent market analysis by FMI highlights several key growth opportunities in the automotive rear seat reinforcement sector.

The increasing demand for spacious and comfortable rear seats is driving market trends. Consumers are showing a clear preference for passenger vehicles that offer enhanced rear seat comfort. To meet this demand, manufacturers are turning to lightweight materials and advanced production techniques to design rear seat reinforcements that boost both safety and comfort.

Innovative technologies are also playing a crucial role in the development of rear seat reinforcement. Modern designs often feature state-of-the-art elements such as integrated seat belts, which enhance overall functionality and safety. The rise of electric vehicles is further accelerating the need for advanced rear seat reinforcement solutions. These solutions are essential for supporting battery packs and maintaining the structural integrity of the vehicle.

Collaboration between automakers and material suppliers is crucial in this evolving market. Together, they are working to develop and refine rear seat reinforcement technologies, ensuring that they meet the latest standards in automotive interior design.

As automotive interior design continues to evolve, the reinforcement of rear seats is becoming increasingly important. The focus on comfort, safety, and innovation is set to drive further advancements in this sector.

The automotive rear seat reinforcement market is experiencing significant growth due to several key factors. Here’s a closer look at what’s fueling this trend:

The growth of the automotive rear seat reinforcement market faces several significant challenges. One major factor is the high cost associated with these systems. In price-sensitive markets, the expense of advanced rear seat reinforcement systems can deter adoption and slow down market growth.

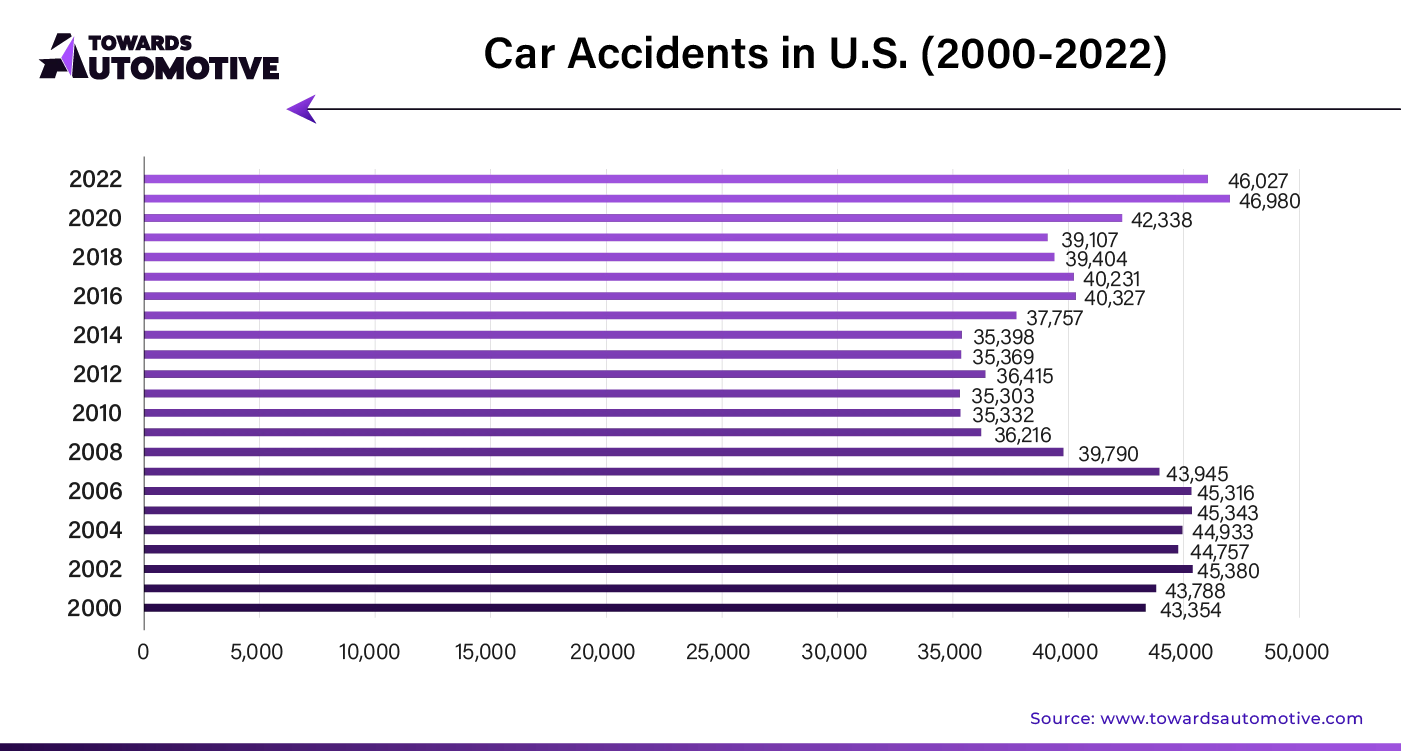

Additionally, the rise in vehicle accidents can negatively impact the market. As the frequency of accidents increases, the demand for rear seat reinforcement systems might be affected, potentially reducing market growth.

Vehicle sales and demand also play a crucial role in shaping the market. Fluctuations in consumer preferences and broader economic conditions can influence market performance. For instance, economic downturns or shifts in consumer behavior can lead to decreased vehicle sales, which in turn can affect the demand for rear seat reinforcement systems.

Moreover, technological advancements in automotive seats, including rear seat reinforcement, present a double-edged sword. While innovations can drive market growth by offering enhanced features and improved safety, they can also lead to higher costs, compatibility issues, and slower implementation processes. These challenges can complicate the adoption of new technologies and impact the overall market growth.

Artificial Intelligence (AI) is revolutionizing the automotive rear seat reinforcement market by enhancing safety, efficiency, and design. AI-driven technologies enable manufacturers to analyze vast amounts of data, leading to the development of innovative reinforcement materials and structures. This data-driven approach allows for the precise prediction of crash impact scenarios and helps in creating more robust and lightweight materials that improve passenger safety.

AI algorithms optimize the design process by simulating various crash conditions and testing reinforcement materials under different scenarios. This accelerates the development of more effective and efficient solutions, reducing time-to-market and costs. Additionally, AI enhances quality control through real-time monitoring and predictive maintenance, ensuring that each reinforcement component meets the highest safety standards.

Furthermore, AI-powered automation in manufacturing processes streamlines production, increases consistency, and reduces human error. As automotive manufacturers strive to meet stringent safety regulations and consumer demands, AI integration will play a crucial role in driving growth in the rear seat reinforcement market, making vehicles safer and more efficient.

In the Automotive Rear Seat Reinforcement market, an efficient supply chain is crucial to meet the growing demand for safety and comfort. The supply chain begins with raw material procurement, where suppliers provide high-quality steel and composite materials. These materials are then transported to manufacturing facilities, where they are processed and shaped into rear seat reinforcement components.

Manufacturers must ensure timely production and quality control, integrating advanced technologies to enhance precision and durability. Once produced, components are distributed to automotive assembly plants, where they are integrated into vehicle frames. Effective logistics and inventory management are key to avoiding delays and maintaining production schedules.

Collaboration with suppliers and logistics providers is essential to address potential disruptions and optimize the flow of materials. This involves real-time tracking, efficient warehousing, and responsive transportation networks. By adopting a streamlined supply chain approach, companies can improve efficiency, reduce costs, and ensure that rear seat reinforcement components meet stringent safety standards. The result is a more reliable and responsive market, capable of adapting to evolving consumer needs and regulatory requirements.

The Automotive Rear Seat Reinforcement (RSR) market is pivotal for enhancing vehicle safety and comfort. This market thrives on several main components and contributions from leading companies.

The primary components of rear seat reinforcement systems include metal brackets, reinforcement bars, and energy-absorbing foam. These elements work together to protect passengers during collisions by reinforcing the rear seat structure and minimizing impact forces.

Companies like Toyota Boshoku Corporation and Faurecia contribute significantly by developing advanced materials and design technologies. Toyota Boshoku focuses on integrating lightweight yet durable materials to improve safety and reduce vehicle weight. Faurecia excels in creating innovative reinforcement systems that enhance crashworthiness and passenger protection.

Additionally, Magna International and Lear Corporation play crucial roles in manufacturing and supplying high-quality reinforcement components. Magna International specializes in producing robust metal reinforcements, while Lear Corporation provides expertise in energy-absorbing materials and structural design.

Spain: Leading the Market with Rapid Expansion

Spain is poised to experience the fastest growth in the automotive rear seat reinforcement sector, with an anticipated CAGR of 5.60% from 2024 to 2034. This robust growth is fueled by the country's significant automotive industry, which plays a crucial role in its economy. As Spain continues to enhance its automotive production capabilities, the demand for reinforced rear seats is expected to soar. SEAT, a leading Spanish automotive manufacturer, is focusing on increasing sustainability and localizing component production, which currently makes up 60% of its Purchasing department's turnover.

United States: Growing Demand for Innovative Rear Seat Reinforcements

In the United States, the market for automotive rear seat reinforcements is projected to grow at a CAGR of 2.20% during the forecast period. This growth is driven by heightened consumer awareness regarding vehicle safety and advancements in rear seat reinforcement technologies. U.S. automakers are heavily investing in R&D to improve vehicle safety, particularly for the increasingly popular SUVs and trucks. The introduction of advanced rear seat reinforcement systems is a response to this growing safety demand.

Canada: Steady Growth Fuelled by Safety Innovations

Canada’s automotive rear seat reinforcement market is expected to expand at a CAGR of 2.40% from 2024 to 2034. This steady growth is due to increased investments in vehicle safety technologies and stringent regulatory standards. Canadian automotive suppliers and manufacturers are developing lightweight yet robust rear seat reinforcement solutions to enhance vehicle efficiency and performance. The rising popularity of crossovers and pickup trucks is further boosting demand for these advanced systems.

United Kingdom: Market Growth Driven by Regulatory Demands and Luxury Trends

In the United Kingdom, the automotive rear seat reinforcement market is projected to grow at a CAGR of 2.70% between 2024 and 2034. Stringent safety regulations and rising consumer expectations for advanced vehicle safety features are driving this growth. The increasing popularity of luxury vehicles has led to the integration of premium rear seat reinforcement technologies, offering enhanced comfort and safety. As UK consumers seek more secure and comfortable seating solutions, the market for advanced rear seat reinforcement systems is expanding.

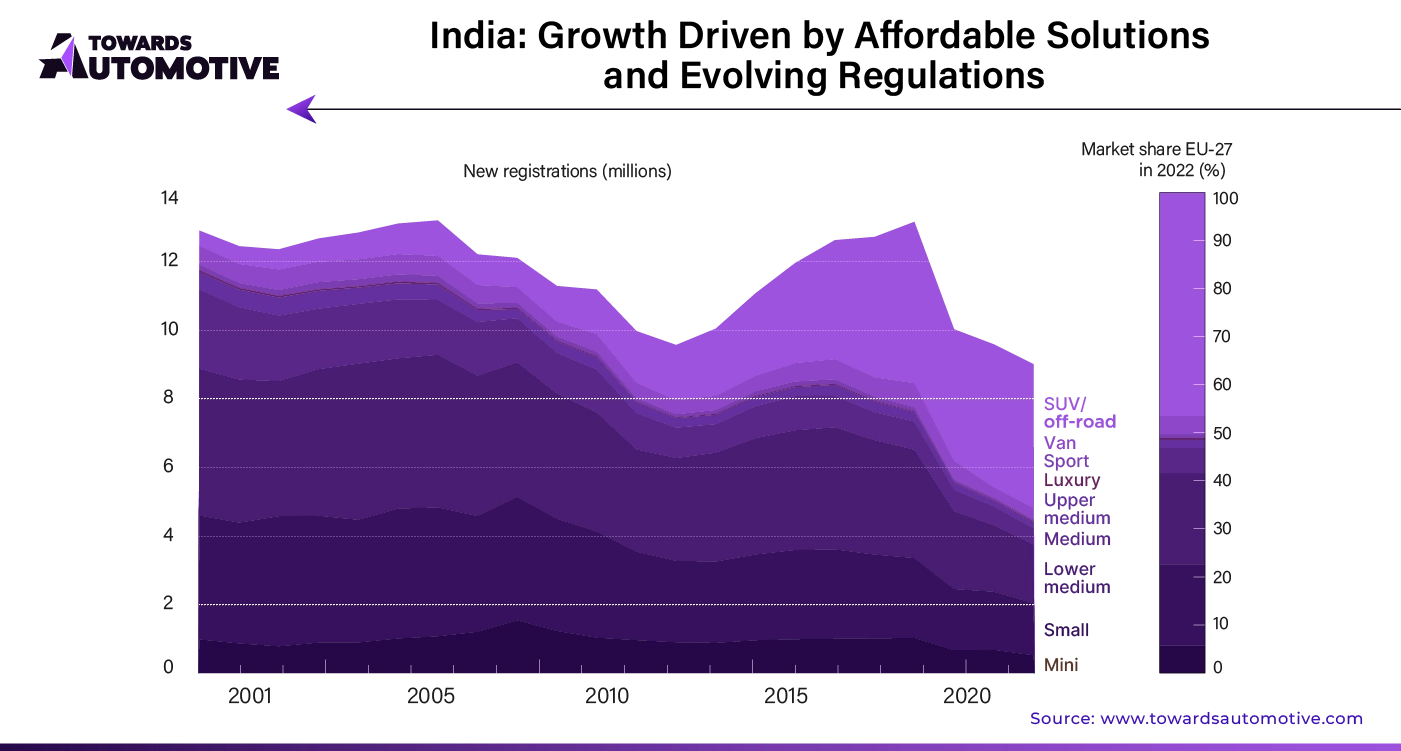

India: Growth Driven by Affordable Solutions and Evolving Regulations

India's automotive rear seat reinforcement market is forecasted to grow at a CAGR of 3.00% over the next decade. This growth is influenced by changing regulatory standards and a rising demand for affordable, compact vehicles. Both international and domestic manufacturers are adopting advanced rear seat reinforcement technologies to enhance safety and comply with regulatory requirements. The increasing market for compact cars necessitates cost-effective solutions that ensure occupant safety.

In 2024, steel and welded plates are expected to dominate the automotive rear seat reinforcement market. Steel is anticipated to capture a commanding 69.80% of the market share, while welded plates are projected to account for 59.50% of the market.

Steel: The Preferred Material for Automotive Rear Seat Reinforcements

Steel will continue to be the leading choice for automotive rear seat reinforcements, holding a significant 69.80% market share by 2024. This dominance is due to steel's superior strength-to-weight ratio, which is essential for ensuring passenger safety during collisions. For manufacturers seeking an economical yet effective safety solution, steel remains an attractive option.

Steel's adaptability allows it to be used in various reinforcement designs tailored to different vehicle architectures and layouts. Vehicles with steel-based rear seat reinforcements are highly valued for their crashworthiness. Moreover, steel’s durability and resistance to corrosion make it ideal for automotive applications, promising long-term reliability.

Welded Plates: A Key Contributor to Structural Integrity

The welded plates segment is set to capture 59.50% of the market share by 2024. Welded plates are favored for their ability to deliver strong rear seat reinforcements, enhancing structural integrity and vehicle safety.

Automakers find welded plate reinforcement machines appealing due to their cost-efficiency and capability to produce customized reinforcement systems. This flexibility allows manufacturers to address specific design requirements for various vehicles. Welded plates are known for their dependable performance and durability, which are crucial for meeting rigorous regulatory standards for crashworthiness and occupant safety.

Strategies for Success in the Automotive Rear Seat Reinforcement Market

To strengthen their positions in the competitive automotive rear seat reinforcement market, companies can adopt several effective strategies. Investing in innovation is a key approach, as developing new frameworks and materials is essential for advancing automotive seat reinforcement equipment.

New entrants looking to establish themselves in the rear seat reinforcement market should focus on several key strategies:

Adient's Sustainability Initiatives: In February 2024, Adient, the world's largest automotive seating manufacturer, released its Sustainability Report 2023. This report outlines the company's achievements in social responsibility, environmental stewardship, and corporate governance. Adient's ProX IsoDynamic Seat and Pure Essential seat exemplify its commitment to sustainability. The Pure Essential seat, designed for electric vehicles (EVs), features eco-friendly materials like green steel and recyclable polyester, promoting circularity and reducing environmental impact.

By Material Type

By Reinforcement Type

By Sales Channel

By Vehicle Type

By Region

April 2025

April 2025

April 2025

April 2025

We offer automotive expertise for market projections and customizable research, adaptable to diverse strategic approaches.

Contact Us