April 2025

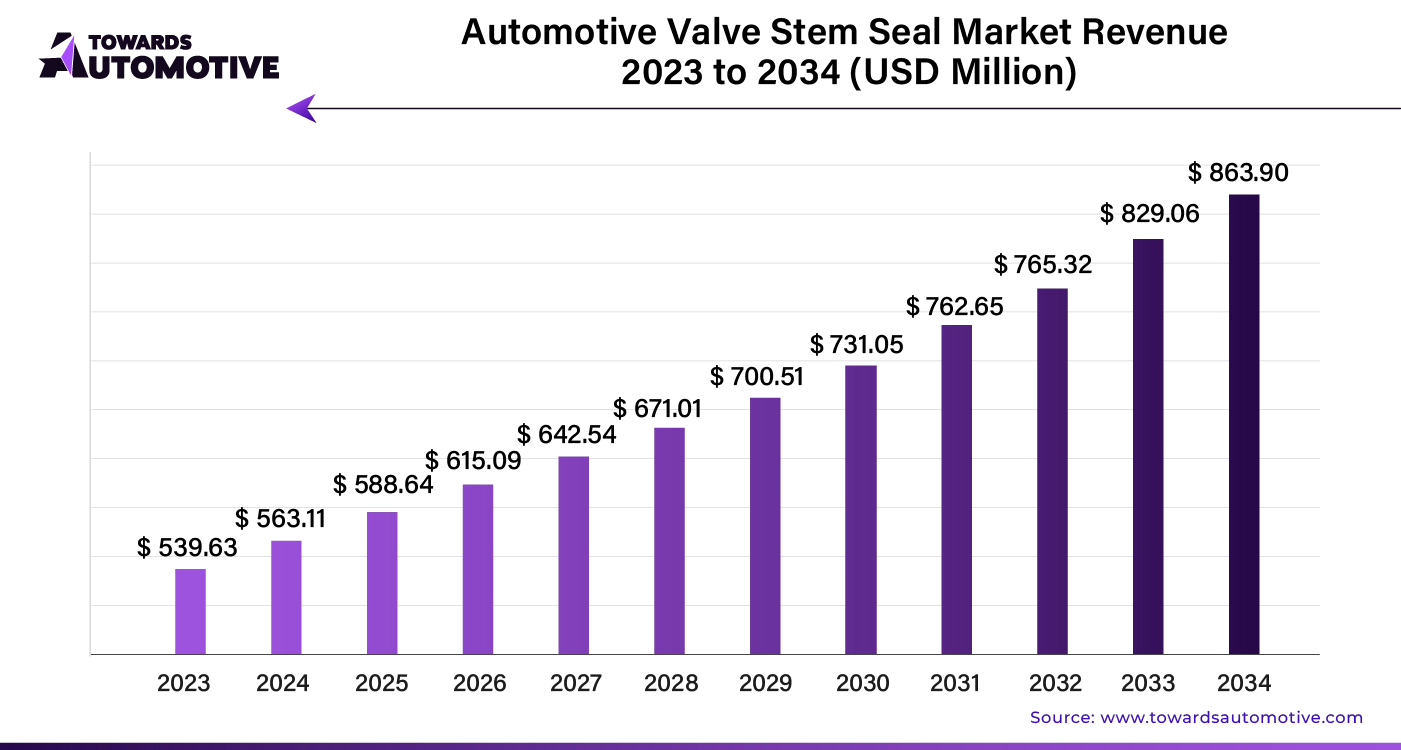

The automotive valve stem seal market is forecasted to expand from USD 588.64 million in 2025 to USD 863.90 million, growing at a CAGR of 4.43% from 2025 to 2034.

Unlock Infinite Advantages: Subscribe to Annual Membership

The rising demand for fuel-efficient vehicles has intensified focus on engine optimization, with valve stem seals playing a key role in reducing friction and enhancing combustion efficiency.

The expansion of the automotive industry, particularly in emerging markets, fuels the need for valve stem seals as essential components in internal combustion engines. Advancements in high-performance seal materials and innovative manufacturing techniques are also propelling market growth.

East Asia is poised to maintain its leadership in the global automotive valve stem seal market, projected to capture approximately 44% of the market share by 2034. Several factors contribute to this strong position:

Synthetic rubber automotive valve stem seals are projected to lead the global market in 2024, capturing a substantial value share of around 62.8%. Their exceptional durability, heat resistance, and low friction make them a top choice.

The robustness of synthetic rubber translates to reduced wear and tear on valve stem seals, which lowers the frequency of maintenance and replacement. This cost efficiency benefits both vehicle owners and manufacturers. The automotive market valued at USD 4,070.19 billion in 2023, is experiencing growth and is projected to surpass USD 6,678.28 billion by 2032, with a significant CAGR of over 5.66%.

These seals enhance engine performance by enduring extreme conditions and high temperatures. Their resilience leads to better engine efficiency, decreased maintenance costs, and overall improved reliability.

A key advantage of synthetic rubber seals is their impressive heat resistance. Poor heat resistance can cause early hardening and cracking, potentially leading to seal degradation and engine damage. Viton®, a high-performance synthetic rubber, is especially valued for its ability to withstand temperatures up to 460° F, making it a reliable option for demanding engine conditions in various vehicles.

The global automotive valve stem seal market is thriving due to the expanding automotive industry. These seals are crucial for internal combustion engines, as they prevent oil leakage and ensure proper lubrication.

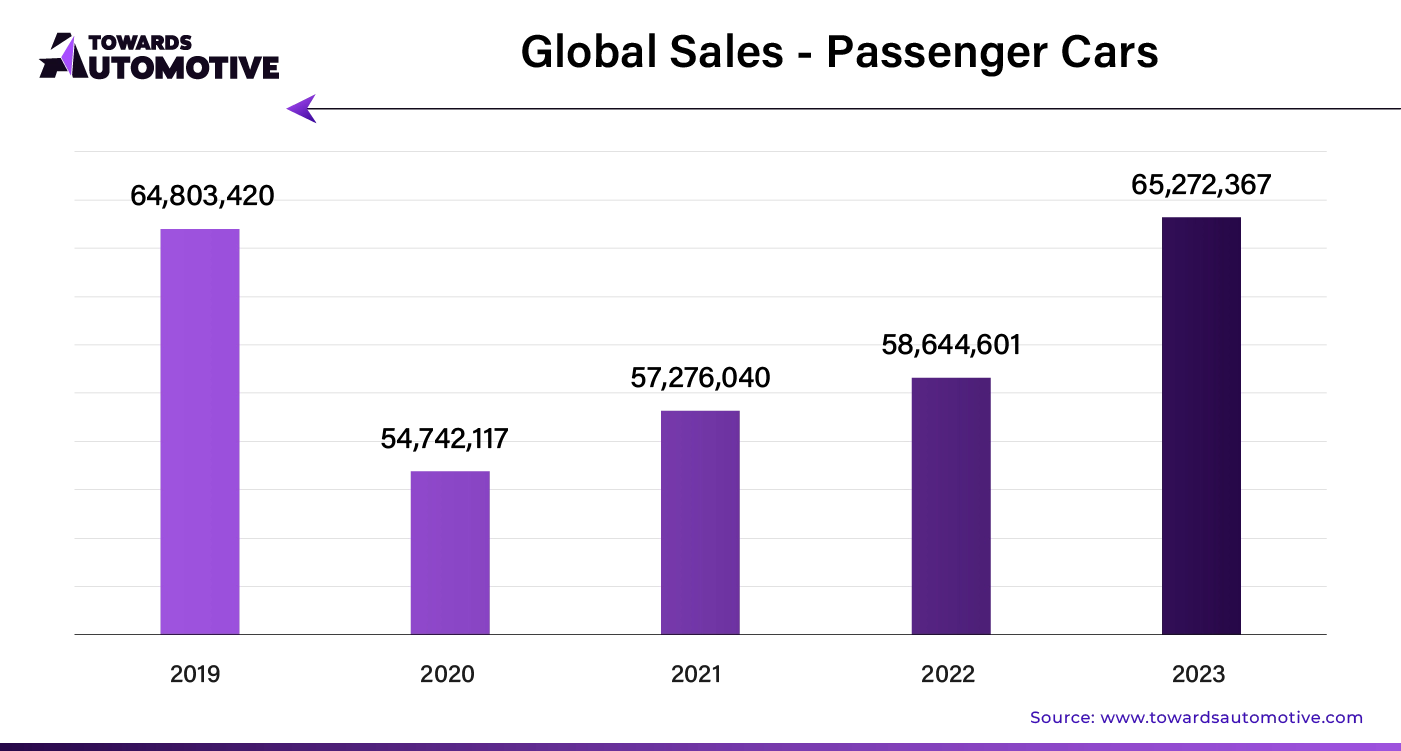

Several factors are shaping the market's growth during the forecast period. Rising vehicle production and sales, advancements in technology, and heightened awareness of emission control are key drivers.

Demand is shifting towards high-quality valve stem seals with advanced materials and technology, reducing the need for frequent replacements. This focus on durability and compliance with stringent regulations is positively impacting market growth.

Environmental concerns and strict emission standards are prompting automakers to produce cleaner, more fuel-efficient vehicles. Automotive valve stem seals play a role in minimizing oil consumption and improving engine efficiency.

Regulations aimed at reducing emissions are increasing the need for advanced valve stem seal technologies that meet environmental standards.

The aftermarket segment is also growing, driven by the wear and tear of older vehicles and the rising number of aging cars, particularly in mature markets.

Geographically, Asia-Pacific is expected to dominate the market due to strong automotive manufacturing in countries like China and India. Europe and North America also contribute significantly, with a focus on adopting advanced technologies.

Key players in the market include Freudenberg Group, Dana Incorporated, Eaton Corporation, SKF AB, and Federal-Mogul LLC. These companies are investing in research and development to introduce innovative products and strengthen their market presence.

The automotive valve stem seals market is poised for significant growth due to rapid advancements in technology, environmental regulations, and evolving consumer preferences.

Fuel efficiency and reduced emissions are major drivers of this growth. Stricter environmental regulations and increased sustainability awareness push automakers to enhance fuel economy. Valve stem seals help achieve this by preventing oil leakage and reducing friction, thereby boosting engine efficiency.

The rise of electric and hybrid vehicles is transforming the automotive industry. Although these vehicles have fewer combustion components, internal combustion engines in hybrids still drive demand for valve stem seals. As electric and hybrid vehicles gain traction, the need for specialized valve stem seals compatible with various powertrains is increasing.

Modern engines are becoming more complex, with turbocharged and direct-injection engines requiring advanced sealing solutions. Valve stem seals must withstand higher temperatures, pressures, and diverse fuels, creating opportunities for innovation in material science and design.

Additionally, the aftermarket segment is set to grow, fueled by the aging vehicle population and ongoing demand for replacement parts. As vehicles age, the need for maintenance and repair services, including valve stem seals, will continue to rise.

AI is set to revolutionize the automotive valve stem seal market by enhancing product innovation and operational efficiency. By leveraging AI algorithms, manufacturers can accelerate the development of high-performance valve stem seals with improved durability and efficiency. AI-driven design tools enable precise simulations and testing, reducing development time and costs.

Predictive maintenance powered by AI will further transform the market. AI systems analyze real-time data from vehicle sensors to predict valve stem seal wear and potential failures, allowing for timely maintenance and reducing unexpected breakdowns. This proactive approach enhances vehicle reliability and extends component lifespan.

AI also streamlines supply chain management. Advanced analytics forecast demand trends, optimize inventory levels, and improve logistics, ensuring that the right products reach the market promptly.

Additionally, AI enhances quality control by detecting defects with greater accuracy during manufacturing. This leads to higher-quality products and reduces the rate of recalls, further boosting market growth.

Overall, AI integration in the automotive valve stem seal market fosters innovation, improves maintenance practices, and optimizes supply chains, driving substantial growth.

The supply chain for automotive valve stem seals operates through a series of coordinated steps designed to ensure efficiency and quality. Initially, raw materials such as elastomers and polymers are sourced from specialized suppliers. These materials undergo rigorous testing to meet industry standards before being sent to manufacturers.

Manufacturers play a pivotal role, utilizing advanced machinery to produce high-quality valve stem seals. Quality control processes are integrated at each stage of production to ensure product reliability and performance. Once manufactured, these seals are distributed through a network of wholesalers and distributors who supply automotive parts retailers and repair shops.

Effective logistics management is crucial in this supply chain. It involves optimizing transportation routes and inventory levels to reduce costs and lead times. Real-time tracking systems enhance visibility and coordination among all supply chain partners.

Collaboration between suppliers, manufacturers, and distributors is essential for addressing demand fluctuations and mitigating disruptions. By streamlining these processes and focusing on quality and efficiency, the automotive valve stem seal market can maintain a robust and responsive supply chain.

The automotive valve stem seal market thrives on the innovation and collaboration of various industry players. Major companies like Trelleborg Sealing Solutions, Federal-Mogul, and SKF drive market growth through their advanced seal designs and manufacturing techniques. Trelleborg Sealing Solutions offers a broad range of high-performance valve stem seals that enhance engine efficiency and durability. Federal-Mogul focuses on producing seals that improve engine reliability and reduce emissions, catering to a global customer base. SKF is renowned for its cutting-edge sealing technology, which contributes to longer-lasting valve stem seals and better engine performance.

These companies significantly impact the market by integrating new materials and technologies into their products. Trelleborg’s innovative materials help in reducing friction and wear, while Federal-Mogul’s emphasis on emission control aligns with global regulatory standards. SKF’s commitment to research and development ensures that their seals meet the latest performance requirements.

Overall, these industry leaders play a crucial role in shaping the automotive valve stem seal market, driving advancements that enhance engine performance and meet evolving automotive standards. Their contributions ensure a dynamic and competitive market landscape.

Tightening Environmental Regulations and Fuel Efficiency Demands

The global automotive industry is undergoing a significant transformation as governments enforce stricter emission standards and push for greater environmental sustainability. This shift positively impacts valve stem seal sales, as these components play a critical role in reducing vehicle emissions. By preventing oil leakage into the combustion chamber, valve stem seals help lower oil consumption and maintain engine efficiency.

Automakers are increasingly adopting advanced sealing solutions to meet eco-friendly standards, driving demand for high-performance valve stem seals.

Rising Vehicle Longevity and Mileage Trends

Consumers are now keeping vehicles longer and driving them further, increasing the need for durable components. Valve stem seals, essential for preventing oil leakage and ensuring engine efficiency, face wear and tear over time. The market for these seals is growing as manufacturers develop more resilient options to handle extended vehicle lifespans and higher mileage.

Investments in new materials and manufacturing techniques are enhancing the durability of valve stem seals, meeting the demands of long-lasting vehicle performance.

Aftermarket Replacement Demand

As vehicles age, the wear on valve stem seals necessitates replacement. The aftermarket sector is a crucial area for replacement parts, with a steady demand for high-quality seals that meet or exceed OEM specifications. This ongoing need for reliable replacement components benefits manufacturers and suppliers in the aftermarket industry.

Global Expansion of Automotive Manufacturing

The automotive industry's expansion into developing regions increases production capacities and vehicle numbers worldwide. This growth translates to greater demand for aftermarket services and replacement parts, including valve stem seals. Aging vehicles contribute to this steady demand, providing opportunities for suppliers to offer high-quality replacement seals. By focusing on these key dynamics, valve stem seal suppliers can navigate the evolving market landscape effectively.

Shift to Electric Vehicles

The automotive industry’s transition to electric vehicles (EVs) is reshaping market dynamics for traditional valve stem seals. As EV adoption rises, demand for these seals decreases, particularly in regions where strict emission standards promote EV use. Unlike internal combustion engines, EVs do not require components like valve stem seals, reducing their relevance.

High Replacement Costs

Replacing valve stem seals is costly and labor-intensive. Although the seals themselves are inexpensive, the replacement process is complex and time-consuming, often taking up to three hours. This extended labor not only increases the overall cost but also discourages frequent replacements. Mechanics charge hourly rates, further driving up expenses, which impacts market demand negatively.

The automotive valve stem seal market is set for notable growth, especially in the United States, China, and Japan. Here’s a breakdown of the market outlook across these leading countries:

China: Leading Market Expansion

China is expected to lead the automotive valve stem seal market with projected revenues of US$ 228 million by 2034 and a strong CAGR of 4.8%. The country's expanding automotive industry and growing consumer vehicle demand are major drivers. China’s efficient manufacturing and competitive pricing also position it as a significant exporter. Furthermore, the increasing demand for high-end and aftermarket valve stem seals is supported by advancements in materials like fluoroelastomers.

Japan: Steady Market Growth

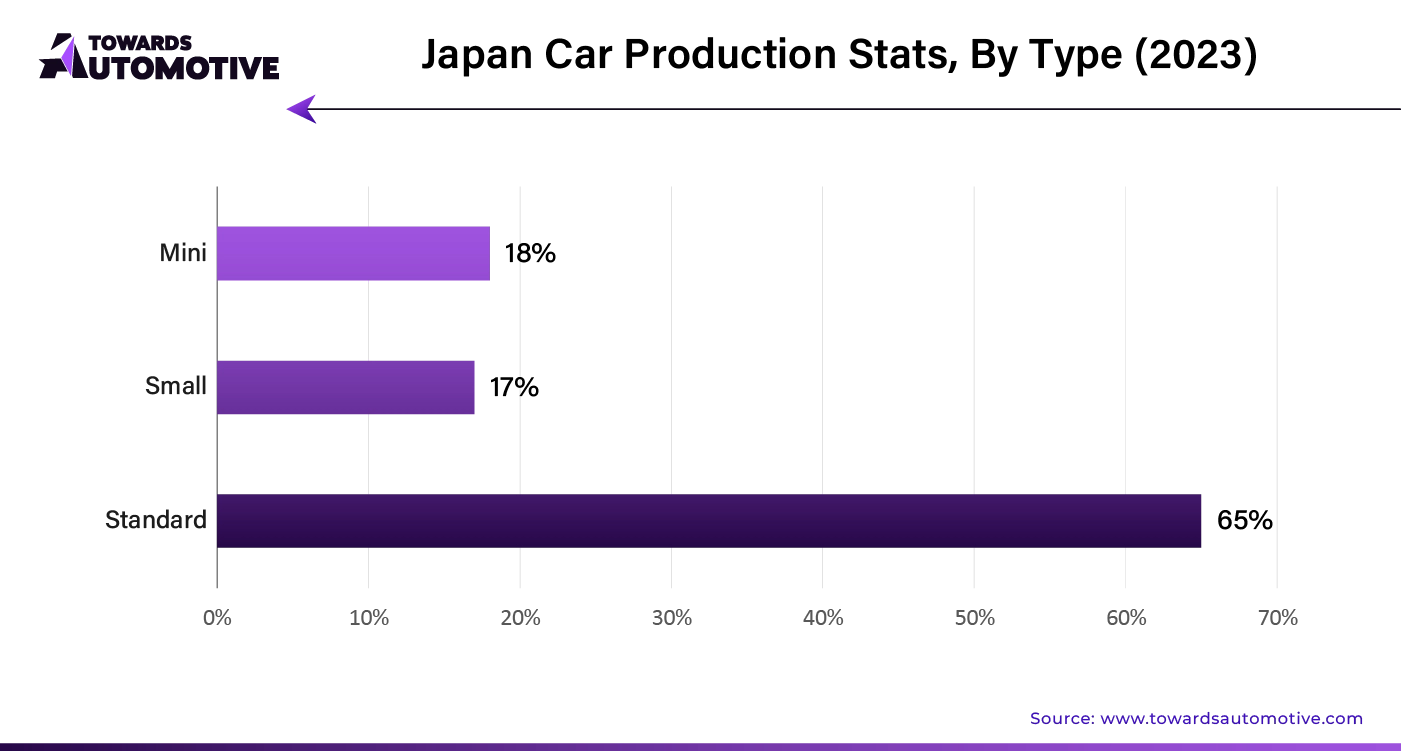

Japan’s automotive valve stem seal market is forecasted to reach US$ 87 million by 2034, growing at a CAGR of 4.4%. The growth is driven by the automotive sector's expansion, rising vehicle exports, and a push for fuel-efficient and high-performance vehicles. Japan’s focus on technological advancements and vehicle maintenance supports the demand for high-quality valve stem seals.

United States: Promising Market Potential

The U.S. market is projected to grow at a 3.7% CAGR, with an anticipated value of US$ 108 million by 2034. Key factors include increased vehicle production, a focus on vehicle maintenance, stringent emission regulations, and growing electric vehicle adoption. The diverse range of vehicles and performance optimization drive the need for high-quality valve stem seals in the U.S. automotive sector.

Passenger Cars to Lead Market Growth

The passenger car segment is projected to lead the automotive valve stem seals market, with an anticipated CAGR of 4.3% from 2024 to 2034. This growth is driven by increasing sales of passenger vehicles and high replacement rates. The trends toward urbanization and rising personal mobility are fueling demand. Technological advancements in safety features, connectivity, and fuel efficiency further enhance the appeal of passenger cars. As these vehicles incorporate more sophisticated technologies, the need for precision-engineered valve stem seals to ensure engine efficiency and longevity becomes more critical.

Gasoline Engines Maintain Strong Market Presence

The gasoline engine segment is set to maintain a substantial market share, growing at a CAGR of 4.6% through 2034. Despite the growing presence of alternative propulsion technologies, gasoline engines remain widely used due to their efficiency and reliability. Valve stem seals are essential for preventing oil leakage and ensuring optimal engine lubrication. As gasoline engines advance to meet stringent emission regulations and improve fuel efficiency, the demand for high-quality valve stem seals continues to rise.

Aftermarket Segment Poised for Significant Revenue Growth

The aftermarket segment is expected to grow at a CAGR of 4.7% during the forecast period. As vehicles age, the need for valve stem seal replacements increases, driving aftermarket sales. Aftermarket solutions provide cost-effective alternatives to OEM products, making them a popular choice among consumers and repair shops. The wide variety of products available in the aftermarket supports diverse vehicle models, ensuring sustained demand and revenue growth.

Auto Valve Stem Seal Market Segmentation

By Product Type

By Design

By Engine Type

By Material

By Vehicle Type

By Sales Channel

By Region

April 2025

April 2025

April 2025

April 2025

We offer automotive expertise for market projections and customizable research, adaptable to diverse strategic approaches.

Contact Us