April 2025

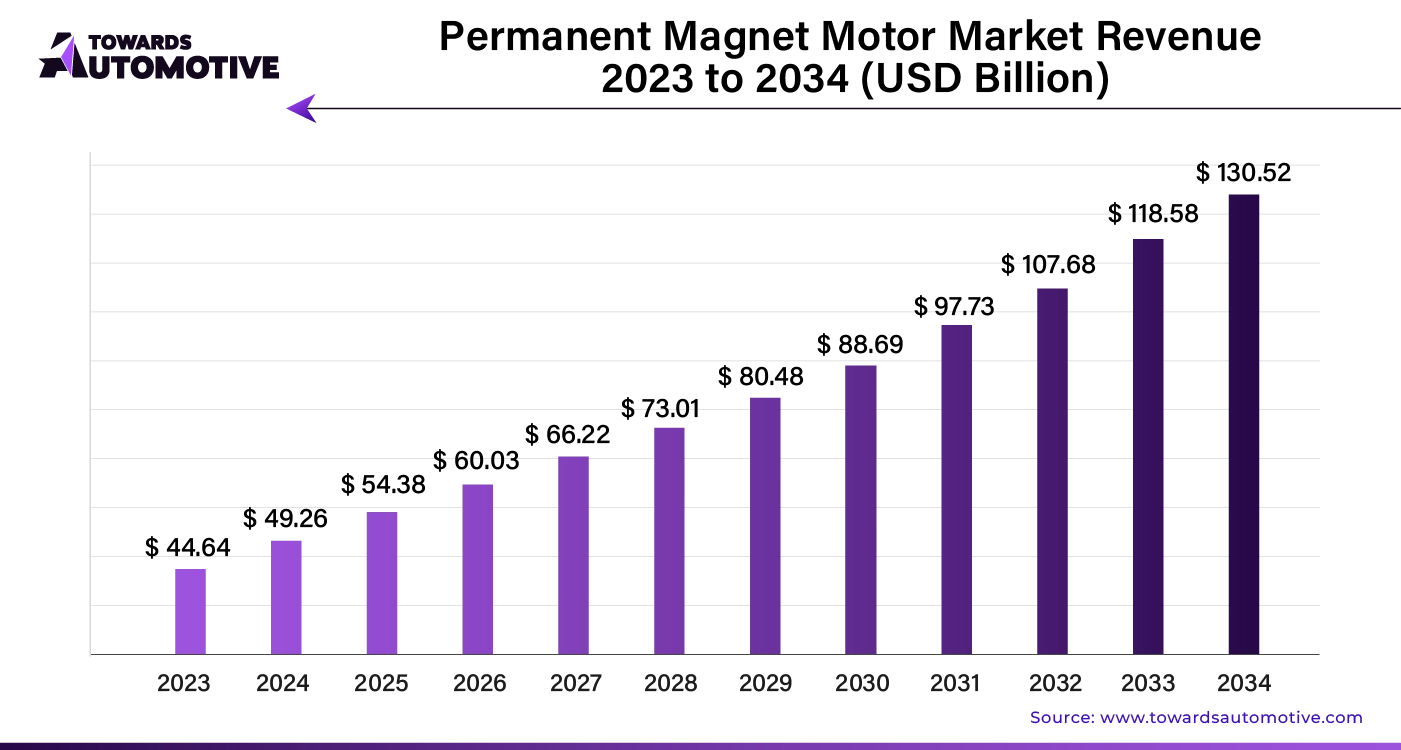

The global permanent magnet motor market size is calculated at USD 49.26 billion in 2024 and is expected to be worth USD 130.52 billion by 2034, expanding at a CAGR of 10.43% from 2023 to 2034.

Unlock Infinite Advantages: Subscribe to Annual Membership

The rise of electric and hybrid vehicles is boosting the use of permanent magnet motors in propulsion systems. As energy-efficient appliances and industrial equipment gain popularity, these motors stand out for their superior efficiency compared to traditional alternatives. The expansion of renewable energy sources, such as wind and hydropower, relies heavily on permanent magnet motors for optimal performance.

Technological advancements are enhancing the performance and reliability of permanent magnet motors, making them increasingly attractive across industries. Supportive government policies are also encouraging the adoption of sustainable technologies, including these motors. The automotive market valued at USD 4,070.19 billion in 2023, is experiencing growth and is projected to surpass USD 6,678.28 billion by 2032, with a significant CAGR of over 5.66%.

Growing consumer and industrial awareness of the benefits—such as reduced energy consumption and lower operational costs—is driving demand. Investment in research and development continues to improve the efficiency and capabilities of permanent magnet motors. Additionally, these motors are finding new applications in fields like robotics, medical devices, and aerospace.

Global efforts to reduce carbon emissions and combat climate change are further pushing industries toward cleaner, energy-efficient solutions like permanent magnet motors.

The global automotive sector is rapidly embracing permanent magnet motors, particularly for electric and hybrid vehicles. These motors are integral to electric propulsion systems, traction motors, power steering systems, and pumps.

Industries like manufacturing, mining, construction, and materials are also increasingly adopting permanent magnet motors. Their superior efficiency, compact size, and enhanced performance compared to traditional motors are key benefits driving this growth.

Renewable energy companies are fueling demand for these motors, especially for wind turbines and hydropower systems. Permanent magnet motors efficiently convert mechanical energy into electrical energy in generators and turbines.

In heating, ventilation, and air conditioning (HVAC) systems, these motors are used in fans, blowers, and pumps to improve air circulation and temperature control in buildings and commercial spaces.

The aerospace and defense sectors are turning to permanent magnet motors for actuators, pumps, and other systems that require lightweight, high-performance motors with precise control.

Additionally, the rise in robotics and industrial automation is boosting the use of permanent magnet motors. Their high torque-to-weight ratios, fast response times, and precise control capabilities are ideal for robotic motion and automation tasks.

Operating and installing permanent magnet motors demands specialized skills and expertise, which is a major obstacle in underdeveloped regions. Additionally, competing technologies like induction and switched reluctance motors limit the broader adoption of permanent magnet motors across various industries. Integrating these motors into existing systems often requires extensive retrofitting or redesign, further hindering market growth.

AI is set to revolutionize the Permanent Magnet Motor (PMM) market by driving efficiency and innovation. Through AI, manufacturers can enhance the design and performance of PMMs, optimizing motor efficiency and reducing energy consumption. AI algorithms enable predictive maintenance, identifying potential issues before they escalate, thus minimizing downtime and repair costs. This leads to increased operational reliability and extended motor lifespan.

Moreover, AI enhances supply chain management by predicting demand patterns and optimizing inventory levels, which reduces costs and improves delivery times. Machine learning models analyze market trends and customer preferences, allowing companies to tailor products more effectively and introduce new features that meet evolving demands.

In production, AI-powered robotics streamline assembly processes, boosting production rates and ensuring consistent quality. These advancements are not only making PMMs more attractive to industries like automotive and renewable energy but also driving overall market growth. As AI technology continues to advance, its integration into the PMM market will likely accelerate, driving further innovations and capturing a larger share of the global market.

In the permanent magnet motor market, an efficient supply chain is essential for meeting growing demand and maintaining competitive advantage. The supply chain begins with sourcing raw materials like rare earth metals, which are critical for producing high-performance magnets. Suppliers of these materials must ensure a steady and reliable flow to manufacturers, minimizing disruptions.

Manufacturers convert these raw materials into permanent magnets and assemble them into motors. To optimize production, manufacturers employ just-in-time (JIT) practices, reducing inventory costs and improving cash flow. Close coordination with suppliers and logistics providers helps prevent delays and maintain production schedules.

Distribution involves shipping completed motors to various end-users, including automotive, industrial, and consumer electronics sectors. Efficient logistics are crucial for timely delivery and cost management. Companies leverage advanced forecasting tools and data analytics to predict demand and adjust supply chain operations accordingly.

Finally, end-users' feedback informs future supply chain adjustments, ensuring that the market adapts to evolving needs. By maintaining flexibility and responsiveness, the supply chain in the permanent magnet motor market supports innovation and growth.

The Permanent Magnet Motor (PMM) market ecosystem relies on several key components, including the rotor, stator, permanent magnets, and electronic control units. Each component plays a crucial role in the motor's efficiency and performance.

Companies like Siemens, ABB, and Bosch drive innovation in the PMM market. Siemens excels in integrating advanced control systems, enhancing motor precision and efficiency. ABB focuses on developing high-performance magnets and integrating them into their motor designs. Bosch contributes by advancing electronic control technologies, ensuring optimal motor performance.

Together, these companies help refine PMM technology, contributing to advancements in automotive, industrial, and consumer electronics applications. Their collective efforts drive the market forward, making PMMs more efficient and versatile.

The permanent magnet motor industry is divided into DC and AC motors. DC permanent magnetic motors are projected to achieve a notable CAGR of 10.00%.

Manufacturers are increasingly turning to DC permanent magnet motors due to their high efficiency, compact size, and precise control. These benefits are driving innovation and boosting productivity across manufacturing, automation, robotics, and renewable energy sectors. As businesses pursue more sustainable and cost-effective solutions, the demand for DC permanent magnet motors is expected to grow.

The permanent magnet motor market is categorized by materials into ferrite, neodymium, and samarium cobalt. Ferrite permanent magnet motors currently lead the market and are anticipated to experience a robust CAGR of 9.70%.

Ferrite motors are preferred for their affordability, durability, and resistance to demagnetization. Their growing popularity spans various applications, including automotive, appliances, electronics, and renewable energy systems.

South Korea: Leading the Charge South Korea stands out with a robust CAGR of 12.00% through 2034. The country's strong emphasis on renewable energy and electric vehicles propels this growth. Major automotive players like Hyundai and Kia are significantly investing in electric vehicle production, further boosting market expansion.

United Kingdom: A Growing Hub The United Kingdom is set to experience a notable CAGR of 11.70% until 2034. The nation’s commitment to sustainability and carbon reduction promotes the use of permanent magnet motors in wind turbines, tidal energy systems, and industrial automation, driving market demand.

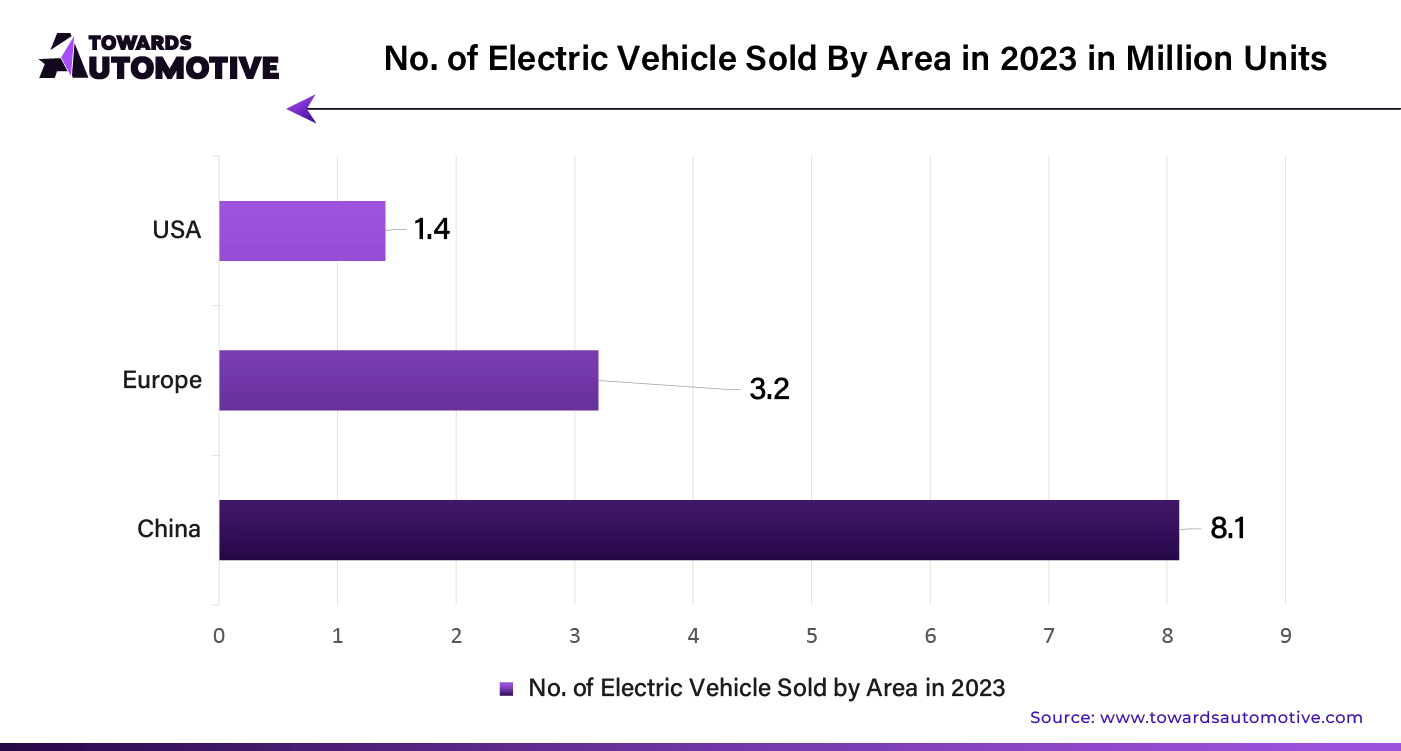

China: A Market Powerhouse China's permanent magnet motor market is projected to expand at a CAGR of 11.00% through 2034. With extensive investments in renewable energy and electric vehicles, China is the world's largest manufacturer of these motors. Government incentives also support widespread adoption across various sectors.

United States: Innovating for Growth The United States is expected to see a CAGR of 10.60% in its permanent magnet motor market by 2034. Increased focus on clean energy, backed by government tax credits and investments in electric vehicle infrastructure, drives demand. The presence of innovative companies and research institutions further fuels market growth.

Japan: Steady Advancement Japan's market for permanent magnet motors is anticipated to grow at a CAGR of 8.70% through 2034. Major automakers are investing in electric and hybrid vehicles, while Japan's focus on efficient energy use promotes the adoption of these motors in renewable energy systems.

This analysis underscores the varied growth trajectories of the permanent magnet motor market across these key countries, driven by technological advancements and strategic investments.

The global permanent magnet motor market features a mix of international and domestic players. Key companies include ABB Limited, Rockwell Automation, Siemens AG, Franklin Electric Company Inc., and Allied Motion Technologies Inc. These leaders focus on developing motors with higher efficiency, advanced functionality, and smart features. They also collaborate with environmental organizations to enhance their reputation and appeal to eco-conscious consumers.

Recent Advancements

By Motor Type

By Magnetic Material Type

By End-user Vertical

By Region

April 2025

March 2025

March 2025

February 2025

Dr. Arjun Patel is a distinguished expert in the automotive industry, holding advanced degrees in Automotive Engineering and Mechanical Engineering. His expertise spans automotive market dynamics, technological advancements, and sustainable practices. Dr. Patel excels in conducting in depth research and analysis on market trends, consumer preferences, and the economic implications within the automotive sector. He is renowned for his insightful publications on topics such as electric vehicles, autonomous driving technologies, and the evolution of sustainable transportation solutions. Dr. Patels research contributions have significantly advanced understanding in the field, earning him recognition as a leading authority in automotive research and analysis.

We offer automotive expertise for market projections and customizable research, adaptable to diverse strategic approaches.

Contact Us